About Fullton

Product Description

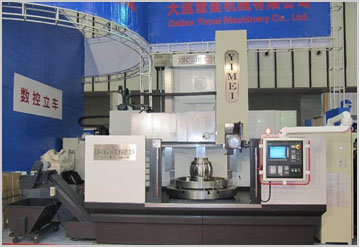

1.Single-column, double-column vertical lathe is a widely used metal turning equipment, applicable to all sectors of the mechanical processing, can be used for internal and external cylindrical surface, conical surface, end surface, grooving and cutting processing, this processing includes rough machining and fine machining, while the CNC Vertical Lathe type more easily be processed into a variety of curved surfaces, thread and so on.

1.Single-column, double-column vertical lathe is a widely used metal turning equipment, applicable to all sectors of the mechanical processing, can be used for internal and external cylindrical surface, conical surface, end surface, grooving and cutting processing, this processing includes rough machining and fine machining, while the CNC Vertical Lathe type more easily be processed into a variety of curved surfaces, thread and so on.

2.The working platform equips with hydrostatic guideway, spindle utilizes NN30(D grade) high-precision radial-type double-row cylindrical roller bearings and thus the working platform possesses strong loading capacity and high turning precision.

3.Vertical tool post equips with a pentagonal knife sets, using rat-gear locating, and side tool post conducts with square tool post, 2 tool post all utilize hydraulic pressure balance (single-column series).

4.Electric part of lathe uses brand-name products, high-level wiring technology, high reliability, and standard grating digital display devices.

5.Machine tool casting uses high-quality resin sand casting process, high-quality castings, after aging treatment, all the steel parts have been quenched and conducted with hardening treatment.

6.Sliding friction parts take the necessary wear-resistant and the reduction of grinding processing (laminating, and quenching), increasing five times abrasion resistance at least, improving the precision to maintain, making the overhaul period to extend over 10 years.

7.The precision inspection of this product carries out JB/T4116—96; JB/T9934.1-1999 precision inspection of CNC vertical lathe is performed

8.Choice of supporting high-quality brand-name parts (hydraulic parts, electrical parts, bearings, standard parts, etc.).

Copyright 2010 Fullton Machinery All rights reversed.